What is the Tevo Tarantula 3D Printer?

The Tevo Tarantula is a popular DIY 3D printer known for its affordability and versatility, making it a favorite among hobbyists and beginners in Australia. It’s a Cartesian-style 3D printer, meaning it moves its print head along the X, Y, and Z axes to deposit material layer by layer. Its open-frame design allows for easy access to the print bed and components, facilitating maintenance and modifications. The Tarantula has gained a strong following in the Australian 3D printing community due to its accessible price point and the extensive support network available online. This has made it a go-to option for individuals looking to explore the world of 3D printing without breaking the bank. Its ability to print with a variety of filaments further enhances its appeal.

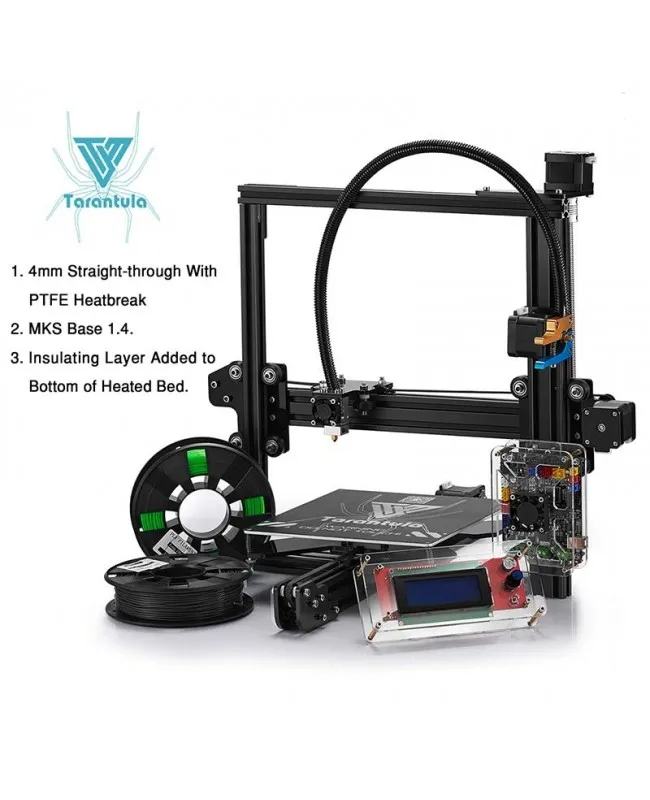

Key Features of the Tevo Tarantula

The Tevo Tarantula boasts several key features that contribute to its popularity. One of the most notable is its large build volume, offering ample space for printing sizable objects. It supports various filament types, including PLA, ABS, PETG, and TPU, providing users with flexibility in their projects. It typically includes a heated bed, essential for printing ABS and other materials prone to warping. Its open-source nature allows users to customize and upgrade the printer with ease. The printer’s ease of assembly is another significant advantage. The Tevo Tarantula is usually sold as a kit, and while assembly is required, the process is generally straightforward, making it a good starting point for those new to 3D printing. The combination of these features makes the Tevo Tarantula a versatile and attractive option.

The Tevo Tarantula’s Design and Build Volume

The Tevo Tarantula’s design is characterized by its open-frame structure, which provides accessibility to the print bed and mechanical components. This open design allows for easy maintenance, adjustments, and modifications. While the build volume can vary slightly depending on the specific model, the Tevo Tarantula typically offers a generous build area, making it suitable for a wide range of projects. The frame is generally constructed from aluminum extrusions, providing a balance of rigidity and weight. This design contributes to the printer’s overall stability during operation. The open-frame design also allows for better ventilation, which can be beneficial for certain filament types, though it may also make the printer more susceptible to drafts and temperature fluctuations in the environment.

3D Printing Technologies and the Tevo Tarantula

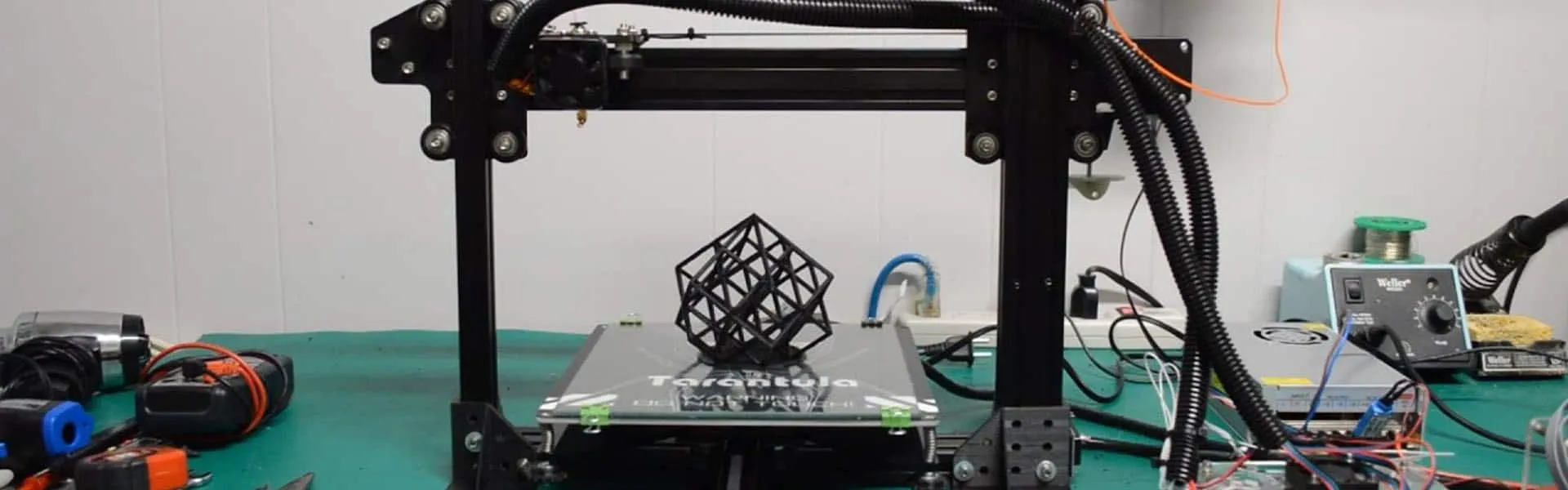

The Tevo Tarantula employs Fused Deposition Modeling (FDM) technology, the most common type of 3D printing. In FDM, a thermoplastic filament is heated and extruded through a nozzle, layer by layer, to build up a 3D object. The Tevo Tarantula uses this process to create models from digital designs. The accuracy and quality of the prints depend on factors like the printer’s calibration, the filament used, and the printing parameters. The printer’s compatibility with different filaments allows users to experiment with various material properties, such as flexibility, strength, and temperature resistance. Furthermore, the Tevo Tarantula’s design is relatively straightforward, making it easier for users to understand the FDM process and troubleshoot any issues that may arise during printing. This simplicity contributes to the printer’s appeal for beginners.

Tevo Tarantula in Australia 5 Must-Know Facts

For those in Australia considering the Tevo Tarantula, here are five key facts. First, it’s an excellent entry-level option due to its affordability and accessible assembly. Second, the Australian online community provides robust support, with numerous forums, tutorials, and user groups. Third, local suppliers in Australia offer filaments, spare parts, and accessories, making it easy to maintain and upgrade your printer. Fourth, the printer’s versatility allows for printing a wide range of objects, from prototypes to functional parts. Fifth, the open-source nature of the Tevo Tarantula encourages customization, allowing you to adapt the printer to your specific needs and interests.

Availability of the Tevo Tarantula in Australia

The Tevo Tarantula is readily available in Australia through various online retailers. Popular platforms include specialized 3D printing stores and general online marketplaces that offer the printer in kit form. It is essential to compare prices and consider shipping costs, as these can vary significantly between suppliers. Checking reviews and ratings from other Australian buyers can help assess the reliability of the seller and the quality of the product. Stock availability can fluctuate, so it’s advisable to check before making a purchase. Furthermore, some retailers may offer bundles that include filament or other accessories, providing additional value for money. Remember to factor in any potential import duties or taxes when purchasing from overseas suppliers.

Where to Buy the Tevo Tarantula in Australia

In Australia, the Tevo Tarantula can be purchased from a variety of sources. Specialized 3D printing stores, both online and physical, are excellent options as they often offer expert advice and a range of related products. Online marketplaces, such as eBay and Amazon, frequently have listings for the Tevo Tarantula from various sellers, making it easy to compare prices. Check the reputation of the seller before making a purchase to avoid any potential issues. Local distributors within Australia also sell the printer, ensuring quicker shipping times and easier access to support. Some educational institutions and maker spaces might also have the Tevo Tarantula available, making them a good option for workshops or group buys. Always compare prices, shipping costs, and warranty options from different vendors to find the best deal.

Tevo Tarantula Cost and Value in Australia

The Tevo Tarantula is known for offering great value for its price. The cost of the printer itself is typically budget-friendly compared to other 3D printers with similar features. It makes 3D printing accessible to a broader audience in Australia. The overall value extends beyond the initial purchase price. The printer’s open-source nature enables users to enhance it with various upgrades and modifications. The availability of affordable replacement parts contributes to its longevity. The active online community in Australia also supports users with troubleshooting advice and project ideas. The low-cost filament options further reduce the ongoing costs associated with 3D printing. Comparing the Tevo Tarantula to more expensive 3D printers, it offers a compelling balance of performance, features, and affordability, making it a strong contender for beginners and experienced users alike.

Setting up the Tevo Tarantula

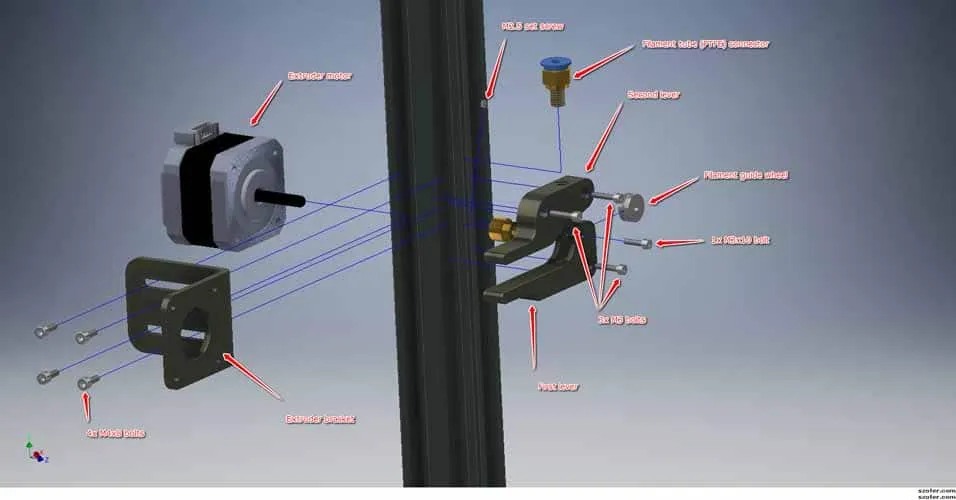

Setting up the Tevo Tarantula involves several key steps. The printer typically arrives as a kit, requiring assembly. The process involves attaching the frame components, installing the motors, wiring the electronics, and calibrating the print bed. Following the assembly instructions provided with the kit is crucial. Numerous online tutorials and videos are available to assist with the assembly process, making it easier for beginners. Calibration is vital for ensuring that the print bed is level and the nozzle is at the correct height. This step will significantly impact the print quality. Once the hardware is assembled, you’ll need to install the necessary software, such as a slicer program, which converts your 3D models into instructions the printer can understand. Fine-tuning the settings in the slicer will optimize the print results. Patience and attention to detail are key during the setup process.

Preparing for Your First Print

Before your first print, several preparations are necessary. Ensure that the print bed is clean and level. Use a leveling procedure, often included in the printer’s firmware or through manual adjustment. Choose a suitable filament for your first project; PLA is a good starting point for beginners because it’s easy to print. Download a 3D model from a website or create your own using 3D modeling software. Import the model into a slicer program and adjust the print settings, such as temperature, print speed, and layer height, based on the filament type. Generate the G-code, which the slicer will create for the printer to follow. Once the G-code is ready, transfer it to the printer’s SD card or connect the printer to your computer. Start the print and monitor the progress. The initial layers are crucial for adhesion, so observe carefully. Have a spatula ready to remove the completed print from the bed.

Choosing the Right Filament for Your Tevo Tarantula

Selecting the appropriate filament is crucial for successful 3D printing. PLA (Polylactic Acid) is a popular choice for beginners because it is easy to print, biodegradable, and emits minimal odors. ABS (Acrylonitrile Butadiene Styrene) is a stronger and more durable material, but it requires a heated bed and can produce unpleasant fumes. PETG (Polyethylene Terephthalate Glycol) offers a balance of strength and ease of printing, making it a versatile option. TPU (Thermoplastic Polyurethane) is a flexible material that can create rubber-like objects. Consider the project’s purpose when choosing a filament. The filament’s diameter is usually 1.75mm, but double-check your printer’s specifications. Read the filament’s specifications for recommended printing temperatures and bed temperatures. Store filaments properly to protect them from moisture. Experimenting with different filament types will enhance your 3D printing skills.

Troubleshooting Common Tevo Tarantula Issues

3D printing can present various challenges, and the Tevo Tarantula is no exception. Some common issues include bed adhesion problems, nozzle clogging, and warping. Bed adhesion issues can be resolved by leveling the bed, using a glue stick, or applying blue painter’s tape. Nozzle clogs can be addressed by cleaning the nozzle with a needle or performing a cold pull. Warping can be minimized by using a heated bed, an enclosure, and adjusting the printing temperature. Other problems include layer shifting, which can be caused by loose belts or incorrect stepper motor settings. Calibration problems can cause inconsistent print quality, requiring adjustment of the steps/mm and PID tuning. Troubleshooting involves identifying the problem, researching potential causes, and implementing solutions. The online community is a valuable resource for solving these issues.

Common Problems and Solutions

Several problems frequently arise when using the Tevo Tarantula, each with corresponding solutions. For example, poor bed adhesion, where the print does not stick to the bed, can be addressed by ensuring the bed is level and using adhesives such as glue stick or painter’s tape. Nozzle clogs, which prevent filament extrusion, can be cleared by heating the nozzle and using a cleaning needle or performing a cold pull. Warping, where the edges of the print curl up, can be resolved by using a heated bed, increasing the bed temperature, and creating an enclosure. Layer shifting, where the printed layers are misaligned, can be due to loose belts, which should be tightened, or incorrect motor settings, which can be calibrated. The best solution involves the correct calibration and adjustment of settings. Addressing these common problems can significantly improve your printing experience.

Tips for Better Prints

Achieving high-quality prints with your Tevo Tarantula involves following several best practices. Calibrating the printer accurately is essential, and bed leveling is especially important. Maintaining the correct printing temperatures for the specific filament is key. Adjusting the bed and nozzle temperatures according to the filament manufacturer’s recommendations will significantly influence print quality. Adjusting the printing speed can also have a major effect. Printing too fast can cause layer shifting, while printing too slow can waste time. Experiment with different print settings to find the optimal balance. Using a raft or brim can improve bed adhesion for complex designs. Ensure proper cooling by using part cooling fans, as required. Regular maintenance and cleaning of the printer will also improve print quality. Finally, stay updated with the latest settings and community advice for improved results.

Upgrading and Modifying the Tevo Tarantula

The Tevo Tarantula’s open-source design makes it highly adaptable for upgrades and modifications. Upgrades can enhance the printer’s performance, print quality, and overall user experience. Common upgrades include replacing the stock hotend with an all-metal hotend to print at higher temperatures, which expands the range of usable filaments. Installing a glass bed or PEI sheet can improve bed adhesion and provide a smoother printing surface. Upgrading the firmware to Marlin can provide advanced features and calibration options. Adding a BLTouch or other auto-bed leveling sensors can simplify the leveling process. Enclosing the printer can help maintain a stable temperature, improving print quality, especially with ABS. Upgrading the extruder to a direct-drive setup can improve the control over the filament. Modifying the printer can be a rewarding process, allowing you to customize it to your specific needs.

Essential Upgrades for Australian Users

For Australian users, specific upgrades can further enhance the Tevo Tarantula. Installing a silent mainboard can significantly reduce the noise generated by the printer. Upgrading the power supply with a higher-quality unit can improve reliability. Installing a filament runout sensor can prevent failed prints. Adding an enclosure can help maintain a stable temperature in the Australian climate, especially in variable conditions. Upgrading to a direct-drive extruder can improve print quality, especially when using flexible filaments. Consider these upgrades based on your needs and the environment in which you are using your printer. Moreover, sourcing these upgrades from local Australian suppliers can ensure faster shipping times and reduce the reliance on international shipping. By adding these modifications, users can customize their Tevo Tarantula to meet their specific requirements.

Safety Precautions for Using the Tevo Tarantula

Safety is paramount when operating a 3D printer. Always monitor the printer during operation and never leave it unattended for extended periods. Ensure proper ventilation in the printing area, especially when printing with materials that release fumes. Keep flammable materials away from the printer. The hotend and heated bed can reach high temperatures, so avoid touching these components during and after printing. Wear appropriate eye protection, especially when removing prints from the bed. Regularly check the wiring and connections for any signs of damage. Install a smoke detector near the printer. Use a fire-resistant enclosure if possible. Familiarize yourself with the printer’s manual and safety guidelines before operation. By following these safety precautions, you can minimize the risks associated with 3D printing.

Operating the Printer Safely

To safely operate the Tevo Tarantula, follow a set of guidelines. Ensure the printer is placed on a stable and level surface before starting. Always plug the printer into a grounded power outlet. Verify all the connections are secure and free from damage before each print. Never attempt to disassemble or modify the printer while it is connected to the power. When the printer is in operation, avoid touching the hotend and heated bed, as they can cause burns. Always wear eye protection and ensure adequate ventilation, especially when printing materials that may release fumes. Regularly inspect the printer for loose parts or wear and tear. Have a fire extinguisher available in the printing area. Following these safety practices will make your 3D printing experience much safer.

Maintenance Tips for Your Tevo Tarantula

Regular maintenance is crucial for the longevity and reliability of your Tevo Tarantula. Regularly clean the print bed, removing any debris or residue with isopropyl alcohol. Lubricate the linear rails and lead screws with appropriate lubricant, such as lithium grease. Tighten belts and screws regularly to prevent vibrations and ensure accurate prints. Inspect and clean the nozzle; a clogged nozzle is a common problem. Check and tighten the wiring connections. Keep the printer environment clean and dust-free. Store filaments properly to prevent moisture absorption. Calibrate the printer periodically, including bed leveling, steps/mm, and PID tuning. Consider replacing worn-out parts proactively. Regularly checking and maintaining your printer can prevent unexpected failures and ensure that it performs at its best.

Keeping Your Printer in Top Condition

Maintaining your Tevo Tarantula in top condition involves a combination of regular maintenance and proactive measures. Regularly clean the print bed using isopropyl alcohol to ensure proper adhesion. Check and tighten all screws and bolts to prevent vibrations. Lubricate moving parts, such as the linear rails and lead screws, to ensure smooth operation. Monitor the condition of the nozzle and hotend, cleaning or replacing them as needed. Inspect the wiring and connections for any signs of wear or damage. Keep the printer environment clean and free from dust and debris. Store your filaments in a dry, sealed container to prevent moisture absorption. Calibrate your printer regularly, including bed leveling and PID tuning. Following these maintenance practices will keep your printer in optimal condition.

The Future of 3D Printing in Australia

3D printing is rapidly evolving, and Australia is poised to be a significant player in its future. Advancements in materials, such as new composites and bio-materials, will expand the applications of 3D printing. The integration of artificial intelligence and automation will streamline the printing process and improve print quality. Increased accessibility and affordability will drive adoption across various industries, from manufacturing and healthcare to education and design. More Australian companies and individuals are adopting 3D printing to reduce prototyping costs, improve design processes, and enable customized manufacturing. The rise of local 3D printing services and support networks in Australia will continue to foster innovation and growth. The Tevo Tarantula, along with other accessible 3D printers, will continue to play a pivotal role in this evolution, enabling more Australians to participate in the 3D printing revolution.