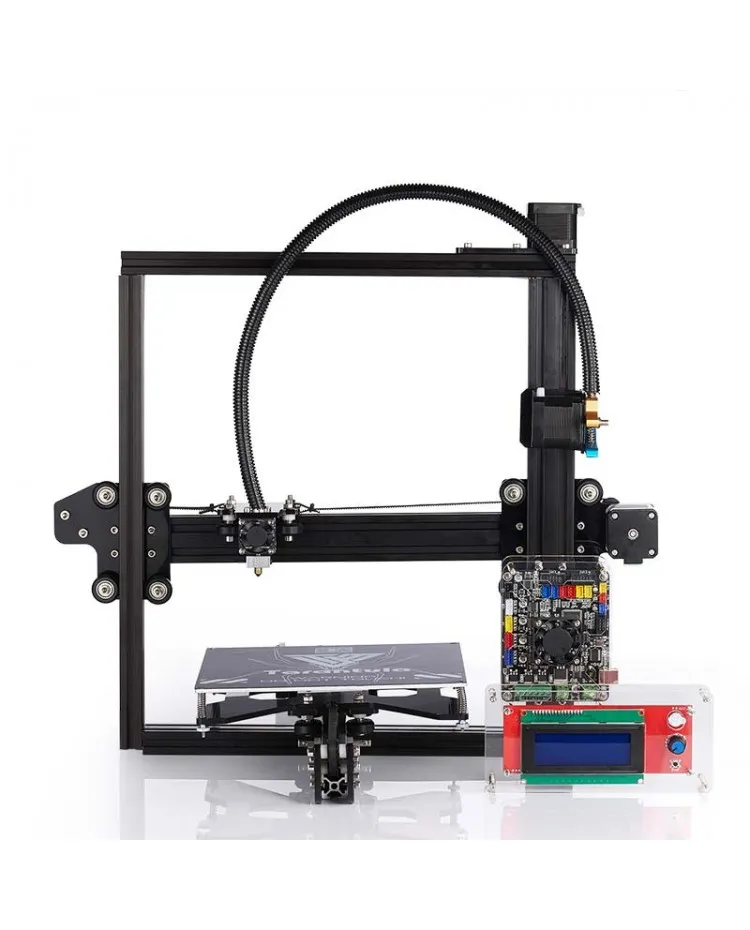

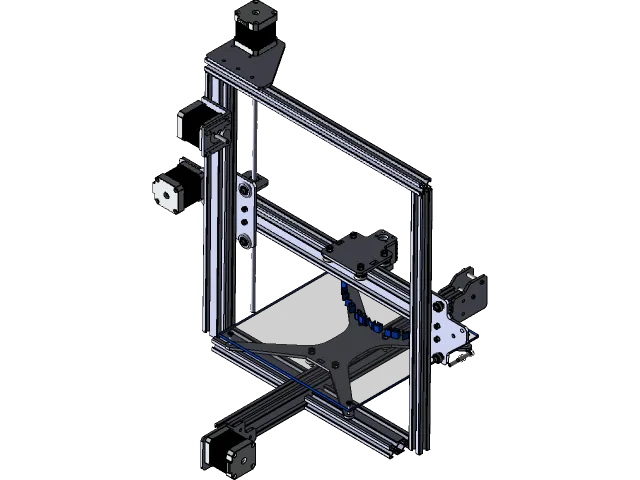

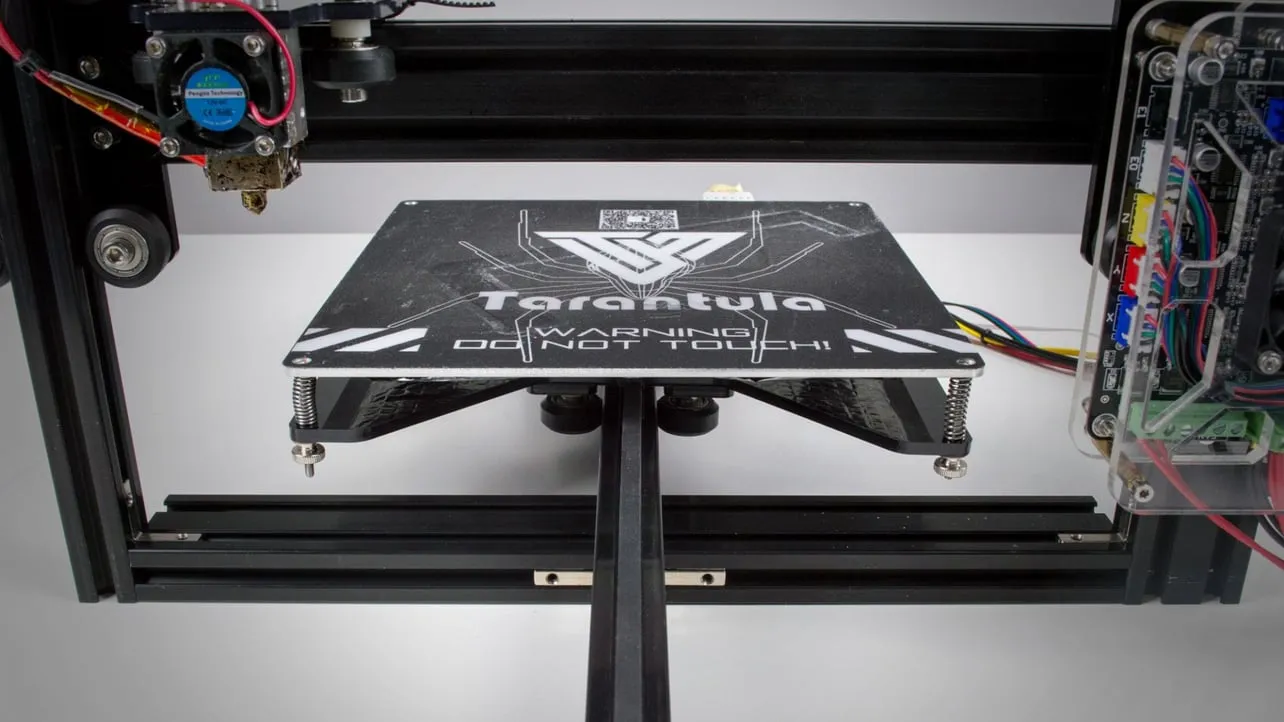

The Tevo Tarantula is a popular and affordable 3D printer, beloved by hobbyists and beginners alike. However, like any entry-level machine, there’s always room for improvement. One of the most impactful upgrades you can perform is replacing the stock hotend with an E3D V6. This seemingly simple swap unlocks a world of benefits, transforming your Tevo Tarantula from a decent printer into a much more capable and versatile machine. This article dives into the top 5 benefits of upgrading your Tevo Tarantula with an E3D hotend, explaining why it’s a worthwhile investment for any serious 3D printing enthusiast.

Enhanced Printing Quality and Precision

The E3D hotend is renowned for its superior design and manufacturing quality, leading to significant improvements in print quality. The precision-machined components minimize play and wobble, resulting in finer details and sharper edges in your prints. This is particularly noticeable in complex geometries and intricate designs, where the E3D hotend excels. The improved thermal stability also plays a crucial role, as the hotend maintains a consistent temperature throughout the printing process, which leads to uniform extrusion and fewer inconsistencies. This, in turn, delivers a smoother surface finish and a more accurate representation of your 3D models. This upgrade means less post-processing, allowing you to enjoy your prints faster.

Improved Layer Adhesion

One of the most immediate benefits of the E3D upgrade is the marked improvement in layer adhesion. The superior thermal performance of the E3D hotend allows for better melting and fusing of the filament layers, creating a stronger bond. This directly translates into more robust and durable prints, less prone to delamination or separation during use. Improved layer adhesion is especially critical for parts subjected to stress or those that require structural integrity. By upgrading to an E3D, you can print with confidence, knowing that your creations will withstand the rigors of real-world applications.

Reduced Stringing and Blobs

Stringing and blobs are common issues in 3D printing, often caused by filament oozing from the nozzle during travel moves. The E3D hotend’s design and thermal characteristics significantly reduce these imperfections. Its precise temperature control and efficient heat dissipation minimize the tendency for filament to ooze, resulting in cleaner prints with fewer stringing artifacts and unsightly blobs. This means less time spent post-processing your prints to remove these imperfections. This improvement saves you time and enhances the overall aesthetic quality of your finished products. You’ll find yourself spending less time cleaning and more time creating.

Greater Filament Compatibility

The stock Tevo Tarantula hotend can be limited in terms of the types of filaments it can handle. The E3D, on the other hand, is designed to work with a much wider range of materials. Its all-metal design allows it to withstand higher temperatures required for advanced filaments like ABS, PETG, nylon, and polycarbonate. This opens up a world of possibilities for your 3D printing projects, enabling you to create functional parts with properties like heat resistance, flexibility, and chemical resistance. Whether you’re interested in printing engineering prototypes or durable end-use parts, the E3D upgrade significantly expands your material options.

Faster Printing Speeds

The E3D hotend, with its improved thermal efficiency, allows for faster printing speeds without sacrificing print quality. It can more effectively melt and extrude filament, enabling a higher flow rate. While the Tevo Tarantula’s frame and mechanics have limitations, the E3D hotend allows the printer to operate closer to its potential. This means you can complete your prints in less time, making your 3D printing workflow more efficient. This increase in speed does not negatively impact your quality, making it an excellent upgrade that brings more efficiency to your workflow.

Higher Printing Temperatures

One of the significant advantages of the E3D upgrade is the ability to print at higher temperatures. The E3D hotend’s all-metal construction allows it to withstand the elevated temperatures required for advanced materials like ABS, nylon, and polycarbonate. This expands your material options, opening doors to more specialized and durable prints. These high-temperature materials often possess properties like increased strength, flexibility, or resistance to heat and chemicals, allowing you to create functional parts that meet specific needs. By upgrading to an E3D, you unlock the potential to tackle a wider range of 3D printing projects and applications.

Wider Material Choices

With the E3D hotend, you are no longer limited to just PLA and basic filaments. The wider temperature range, combined with the hotend’s design, allows you to use a vast range of filaments. From flexible TPUs to strong and durable nylons and carbon fiber composites, the E3D gives you the ability to print anything. This will give you the freedom to experiment and create. With the E3D, you can choose the best material for the job, allowing you to print functional prototypes, end-use parts, and everything in between. This upgrade truly expands your capabilities.

Increased Durability and Reliability

E3D hotends are known for their robust build quality and reliability. They are designed to withstand the rigors of continuous 3D printing, with high-quality components and precise manufacturing. This translates into a longer lifespan for your hotend, minimizing the need for frequent replacements. The improved durability also means less downtime due to clogs or malfunctions, allowing you to rely on your 3D printer for projects. The long-term reliability of the E3D hotend ensures consistent performance, minimizing the need for troubleshooting and maintenance.

Reduced Clogging and Maintenance

The E3D hotend’s design incorporates features that minimize the chances of clogging. The smooth internal surfaces and precise tolerances reduce the likelihood of filament buildup and blockages. Even if a clog occurs, the E3D is often easier to disassemble and clean compared to the stock hotend. This means less time spent troubleshooting and more time printing. The improved reliability of the E3D reduces maintenance requirements, allowing you to focus on creating your 3D prints.

Extended Lifespan of the Hotend

The E3D hotend, built with high-quality materials and precision engineering, boasts a significantly longer lifespan than the stock hotend. This results from the robust design and the ability to withstand the stresses of continuous operation. This extended lifespan translates to lower long-term costs as you won’t need to replace the hotend as frequently. While the initial investment may be higher, the increased durability and reduced maintenance of the E3D hotend will provide you with a solid return over time.

Overall Cost-Effectiveness

While the initial cost of an E3D hotend upgrade is higher than the stock option, it offers excellent value for the money. The benefits, including improved print quality, expanded material compatibility, and increased reliability, outweigh the initial investment. Over time, the E3D hotend can save you money by reducing the need for replacements and minimizing wasted filament due to failed prints. Considering all the advantages, the E3D upgrade is a cost-effective solution that will enhance your 3D printing experience.

Initial Investment vs. Long-Term Savings

The E3D hotend requires an initial investment. However, the long-term savings become evident through several factors. The increased durability means fewer replacements, reducing costs over time. Additionally, the improved print quality and reliability minimize the chances of failed prints, leading to less wasted filament and materials. The ability to use a wider range of filaments also provides cost-saving opportunities by allowing you to select the most economical material for your specific project. Furthermore, a well-maintained E3D hotend can significantly outlast the stock hotend, increasing its value. It’s an investment that quickly pays for itself.

Upgrading vs. Buying a New Printer

When considering improvements to your 3D printing setup, you might weigh the option of upgrading components against purchasing a new printer. The E3D hotend upgrade offers a cost-effective alternative to buying a new machine, providing significant improvements in print quality, material compatibility, and reliability. This upgrade will give you performance boosts at a fraction of the cost of a new printer. This allows you to significantly improve your Tevo Tarantula’s capabilities without the expense of a full replacement. The E3D upgrade is a smart choice for maximizing the potential of your current 3D printer.

In conclusion, upgrading your Tevo Tarantula with an E3D hotend is a smart investment that brings considerable benefits. From improved print quality and reliability to wider material compatibility and faster printing speeds, the advantages are clear. While there’s an initial cost, the long-term savings and enhanced printing experience make it a worthwhile upgrade. If you’re seeking to elevate your 3D printing capabilities, the E3D hotend is a powerful upgrade that will deliver excellent results.