Why Invert the Z-Axis on Your Tevo Tarantula?

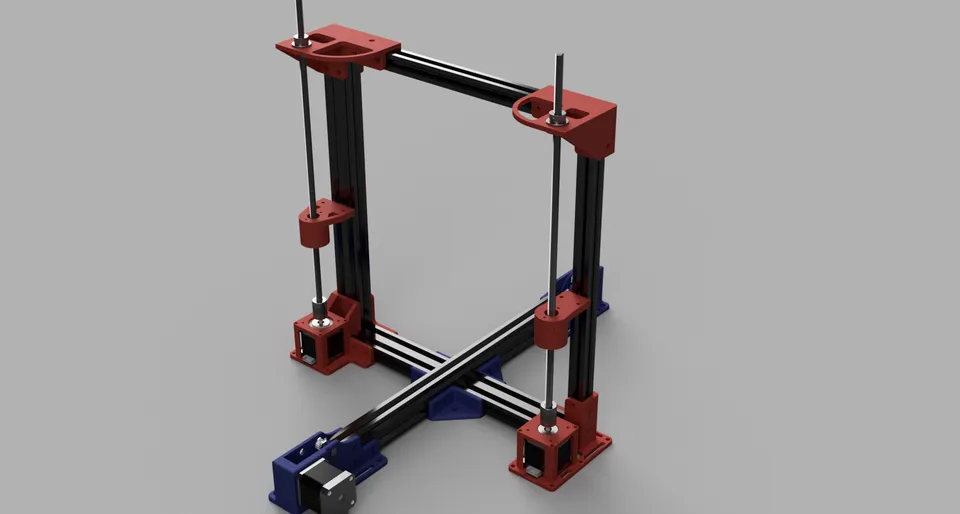

The Tevo Tarantula is a popular 3D printer known for its affordability and community support, however, one common modification that improves print quality is inverting the Z-axis. This seemingly simple change can lead to significant improvements in print quality and user experience. By flipping the orientation of the Z-axis, you’re essentially moving the heavy components like the print bed downwards, rather than having them supported by the Z-axis leadscrews from below. This modification changes the dynamics of how your printer operates, introducing several key advantages that can drastically improve the performance of your Tevo Tarantula. It is a relatively simple upgrade that can make a significant difference.

Benefits of an Inverted Z-Axis

Inverting the Z-axis on your Tevo Tarantula offers several key advantages. These improvements contribute to better print quality, easier maintenance, and an overall enhanced user experience. The benefits go beyond just aesthetic improvements. Implementing this upgrade will lead to more reliable prints and more enjoyable 3D printing experiences. It’s a modification that addresses several common issues and enhances the printer’s capabilities. These advantages collectively make the inverted Z-axis a highly recommended upgrade for any Tevo Tarantula owner looking to improve their printing experience and quality.

Increased Print Bed Stability

One of the most significant benefits is the increased stability of the print bed. With the inverted configuration, the print bed is suspended from above rather than supported from below. This setup reduces the stress on the Z-axis leadscrews and minimizes any potential for the bed to wobble during printing. By hanging the bed, any movement is resisted by gravity, leading to significantly reduced vibrations. This stability is crucial, especially during the initial layers of a print, as it directly impacts adhesion and dimensional accuracy. Stable foundation is created, resulting in more consistent layer lines and overall better print quality. This enhances the ability to print with a wide variety of filaments, from PLA to more demanding materials. It results in more robust prints with superior overall quality.

Reduced Z-Wobble Potential

Z-wobble, a common issue in 3D printing where vertical lines appear wavy on the printed object, is significantly reduced. This problem arises from minor imperfections or binding in the Z-axis leadscrews or motor couplings. By inverting the Z-axis, the weight of the print bed and the printed object is now pulling down on the leadscrews, minimizing the impact of any small imperfections. The leadscrews are less likely to bend or flex, which further decreases the potential for Z-wobble. As a result, your prints will have straighter, smoother vertical surfaces, leading to higher-quality prints. This is especially noticeable in tall prints where Z-wobble is more pronounced. This improvement enhances the aesthetic and structural integrity of your prints.

Simplified Access to the Print Bed

The inverted Z-axis configuration often provides easier access to the print bed. With the print bed lowered, it becomes simpler to remove finished prints, clean the bed surface, and make adjustments. This is particularly useful when using adhesive aids, such as glue stick or tape, as you can easily reach the entire surface without obstructions. This design also makes it more convenient to visually inspect the first layer adhesion during printing. This simplification streamlines the printing process and contributes to a more user-friendly experience. This is a small, but valuable improvement that enhances usability, making maintenance and print removal easier.

Planning Your Tevo Tarantula Inverted Z Upgrade

Before diving into the conversion, thorough planning is crucial. Proper preparation ensures a smooth installation process and minimizes potential issues. A well-planned upgrade saves time, reduces frustration, and helps you avoid costly mistakes. This section covers everything from gathering the necessary tools and parts to preparing the printer for the modification. Careful planning contributes significantly to the overall success and satisfaction of the upgrade. This ensures that the conversion is as trouble-free as possible. Remember to consider your printer’s current condition and any existing modifications. Take the time to prepare correctly.

Gathering the Necessary Tools and Parts

To successfully convert your Tevo Tarantula to an inverted Z-axis setup, you’ll need a selection of tools and specific parts. This list covers both the basic tools and the essential components required for the modification. Having everything prepared in advance will help to prevent delays and make the upgrade process much more manageable. Preparing these items beforehand will streamline the process and make it easier to follow the step-by-step instructions. It’s important to verify that you have everything on this list before starting the conversion to ensure a seamless and successful upgrade experience. Make a checklist to ensure that all needed items are accounted for.

Essential Tools and Materials

- Set of Allen wrenches

- Screwdrivers (Phillips head and flathead)

- Wire strippers and crimpers

- Soldering iron and solder (optional, for wire modifications)

- Multimeter (for checking wiring)

- 3D printer bed leveler (optional, for precise bed leveling)

- Cutting mat or surface protection

- Zip ties or cable management clips

Required Hardware for Inversion

- New motor mounts (designed for inverted Z-axis setup)

- Longer Z-axis leadscrews (ensure correct length)

- Screws and bolts (matching those used on the original Z-axis)

- Wire extensions (if needed, for motor and endstop wiring)

- Heat shrink tubing (for wire connections)

Step-by-Step Tevo Tarantula Inverted Z Conversion Guide

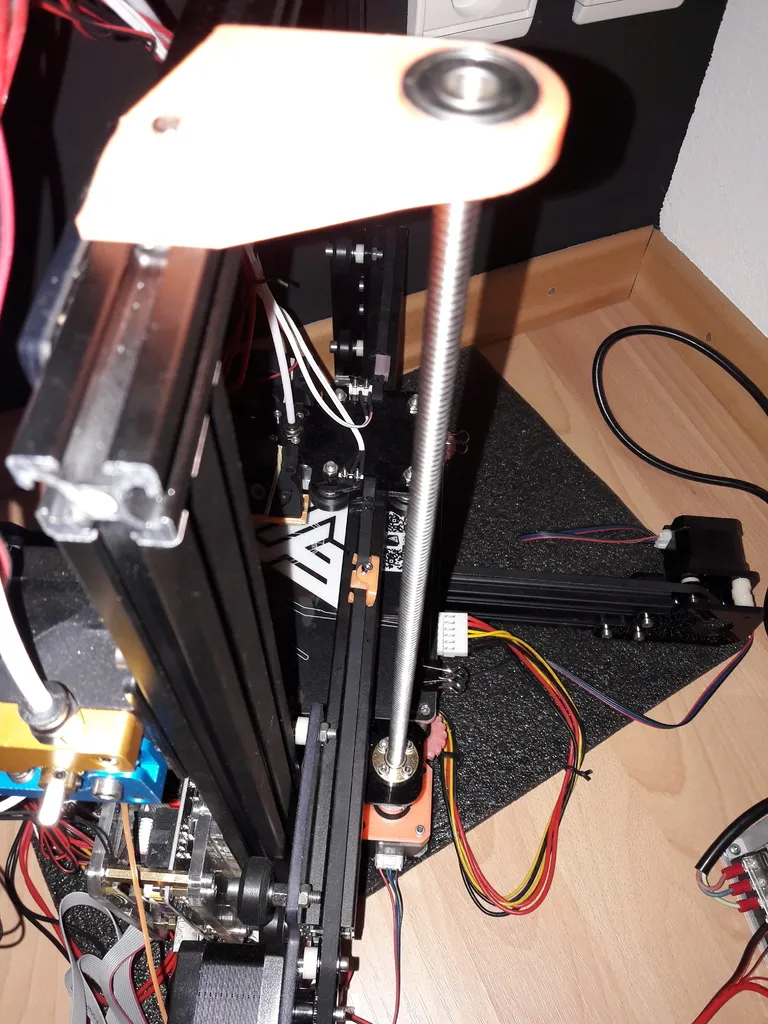

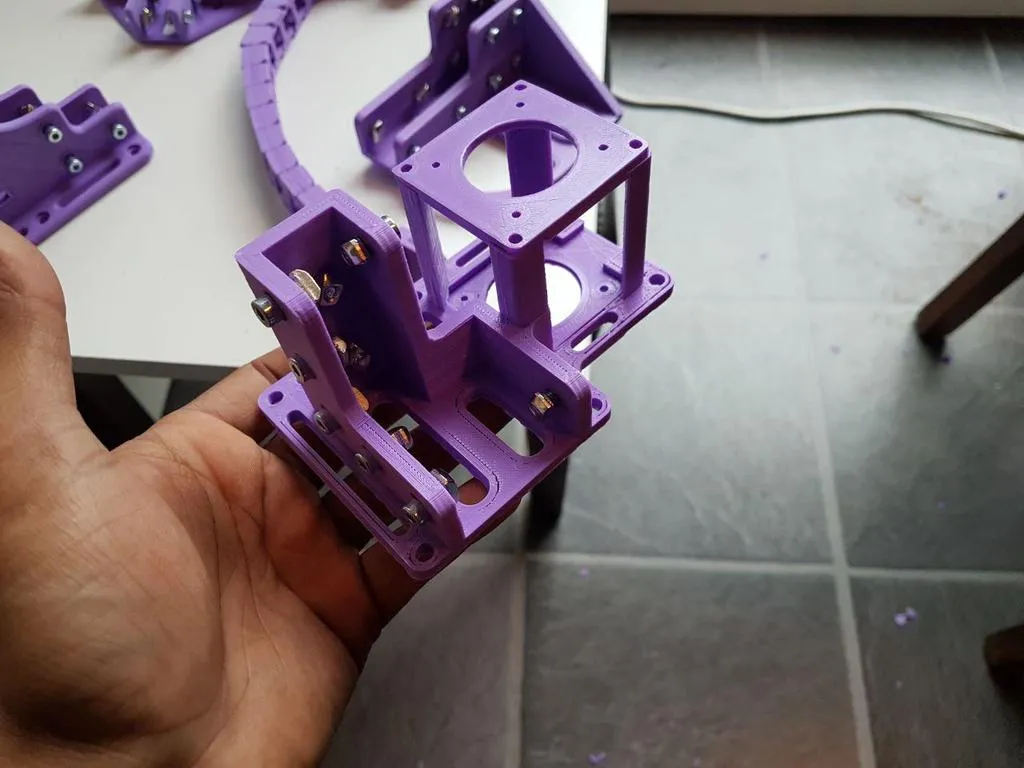

Follow these steps for a successful conversion. Each step is clearly outlined to ensure the entire process is manageable. This straightforward guide will allow you to successfully implement the inverted Z-axis modification, boosting your printer’s performance. Taking it slow and double-checking your work at each step will prevent any mistakes. By carefully following these instructions, you will be able to make the modifications and start enjoying the benefits of an inverted Z-axis on your Tevo Tarantula. Refer to the images provided throughout the guide for visual assistance and confirmation.

Disassembly of the Existing Z-Axis

Begin by carefully disconnecting the power supply and any external connections to your Tevo Tarantula. This step is essential for safety and prevents any electrical hazards during the modification process. Next, remove the print bed and any attachments, such as the glass or build surface, to make the following steps easier. This provides better access to the components and minimizes the risk of accidental damage during disassembly. Now you can move on to removing the Z-axis motors and leadscrews. Take pictures to help guide you.

Removing the Z-Axis Motors

Carefully detach the Z-axis motors from their current mounts. Unplug the motor wires from the control board. Make sure to label the wires to ensure easy reconnection later. Next, remove the motor mounting hardware, such as screws or bolts, securing the motors to the frame. Once the screws are removed, carefully detach the motors from the frame. This frees the motors from the existing setup and prepares them for the inversion. Place the motors and hardware in a safe place for reassembly. This is a critical stage in the disassembly process. Now that the motors are detached, the next step is to remove the leadscrews.

Detaching the Z-Axis Leadscrews

Carefully detach the Z-axis leadscrews from the motor couplings and the top frame supports. This step usually involves loosening set screws on the couplings. Then, gently remove the leadscrews from their current positions. Set aside the leadscrews, as you’ll be reusing them in the inverted setup. Once the leadscrews are detached, you will prepare for the new motor mounts. This process enables you to reconfigure the leadscrews in their new inverted orientation.

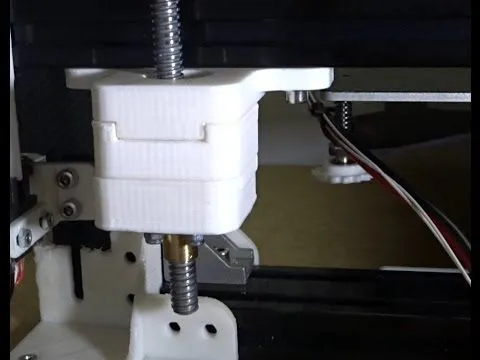

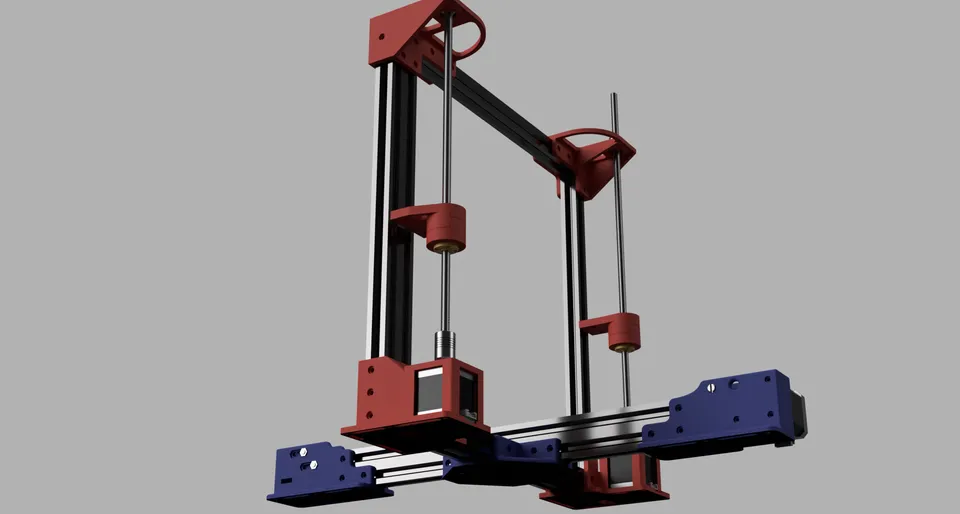

Mounting the Z-Axis Motors and Leadscrews

Attach the new motor mounts to the printer frame. Ensure that the motor mounts are correctly positioned and securely fastened. This establishes the framework for your inverted Z-axis configuration. Next, install the Z-axis motors onto the new motor mounts, following the instructions provided with the mounts. This step involves aligning the motor shafts with the leadscrews. Secure the motors with appropriate hardware. Finally, connect the leadscrews to the motor couplings. Be sure to securely tighten the set screws to avoid any slippage. This will provide a stable and precise Z-axis control.

Installing the New Motor Mounts

Carefully align the new motor mounts on the frame of your Tevo Tarantula. Ensure the mounts are positioned correctly to support the inverted Z-axis setup. Use the appropriate screws and bolts to secure the motor mounts to the frame. Make sure that the mounts are firmly attached and stable. If the motor mounts require any specific orientation, follow the manufacturer’s instructions carefully. Double-check the mounting to avoid any potential issues during operation. Correct installation is crucial for the mechanical integrity of the inverted Z-axis.

Reversing the Z-Axis Leadscrews

The leadscrews are now positioned to operate in the inverted configuration. This may include the need to use longer leadscrews. These longer leadscrews support the build plate in its new downward orientation. Ensure the leadscrews are correctly aligned with the motor couplings and top supports. Fasten the leadscrews securely to prevent any movement. This step is essential for the printer to function properly with the inverted setup. Confirm proper alignment. If the printer has a dual Z setup, the alignment should be exactly the same for both sides. Ensure that all screws are tight and secured.

Wiring and Configuration Adjustments

Once the mechanical components are in place, you will need to make changes to the wiring and the firmware. Ensure that the motor wires are correctly connected to the control board. If you extended any wiring, ensure that the connections are secure and insulated. If necessary, update the motor direction in the printer’s firmware. Without these corrections, the printer’s movements could be incorrect. Take the time to make the configuration adjustments needed to support the inverted Z-axis setup. These software changes are essential for the printer to function as expected.

Adjusting Firmware Settings

Access the firmware settings on your Tevo Tarantula, typically through the printer’s LCD screen or by connecting to a computer. Locate the Z-axis motor direction setting and reverse the direction. This will ensure that the Z-axis moves in the correct direction when commanded. Confirm the settings after making the changes. Also, recalibrate the steps/mm for the Z-axis leadscrews to compensate for any differences in the leadscrew pitch. Properly configured firmware settings are essential for the printer’s performance. This ensures correct movement of the Z-axis.

Calibration and Testing

After completing the physical and software modifications, thorough calibration and testing are essential. This section covers the necessary steps to guarantee the inverted Z-axis functions as intended. Carefully calibrating the Z-axis will ensure that your prints have accurate layer heights and excellent quality. Performing these tests helps to verify that all aspects of the setup are functioning correctly. The primary goal is to refine the printer’s settings. This section helps you fine-tune the printer’s performance.

First Layer Calibration

Proper first-layer calibration is key to print success. Use the printer’s auto-leveling feature, if available. If not, manually adjust the bed level. Then, print a test square or a series of lines to fine-tune the bed’s height. The nozzle should be the correct distance from the bed to ensure proper adhesion. Observe the first layer as it prints, and adjust the Z-offset if needed. If the nozzle is too close, the filament will be squished, and if it is too far, the filament will not adhere. Continue making small adjustments until the first layer is perfect. The goal is to achieve a smooth and uniform first layer for successful prints. Taking the time to get the first layer perfect is time well spent.

Troubleshooting Common Issues

Even with careful planning and execution, you might encounter a few problems during the upgrade. One common issue is motor direction, which can be fixed by reversing the motor wiring or the firmware setting. Another potential problem is Z-wobble, which can be caused by binding or misalignment. Carefully inspect the leadscrews for straightness and alignment. Adjust the alignment if needed, or consider upgrading to higher-quality leadscrews. If your printer still does not print properly after the upgrade, consult the user manual or online resources for support. This process will help you identify and resolve any remaining issues. The goal is to correct any issues and ensure that the printer is working correctly.

This guide provides a detailed walkthrough for inverting the Z-axis on your Tevo Tarantula. By following these steps, you can enhance your printer’s performance and overall print quality. The inverted Z-axis modification is an investment that contributes to more reliable and high-quality prints. Remember to take your time, double-check your work, and enjoy the process of upgrading your 3D printer. This modification offers significant advantages for anyone looking to improve their 3D printing results.