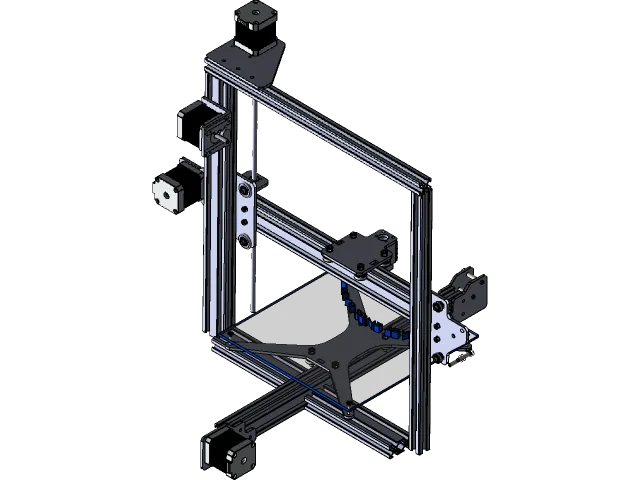

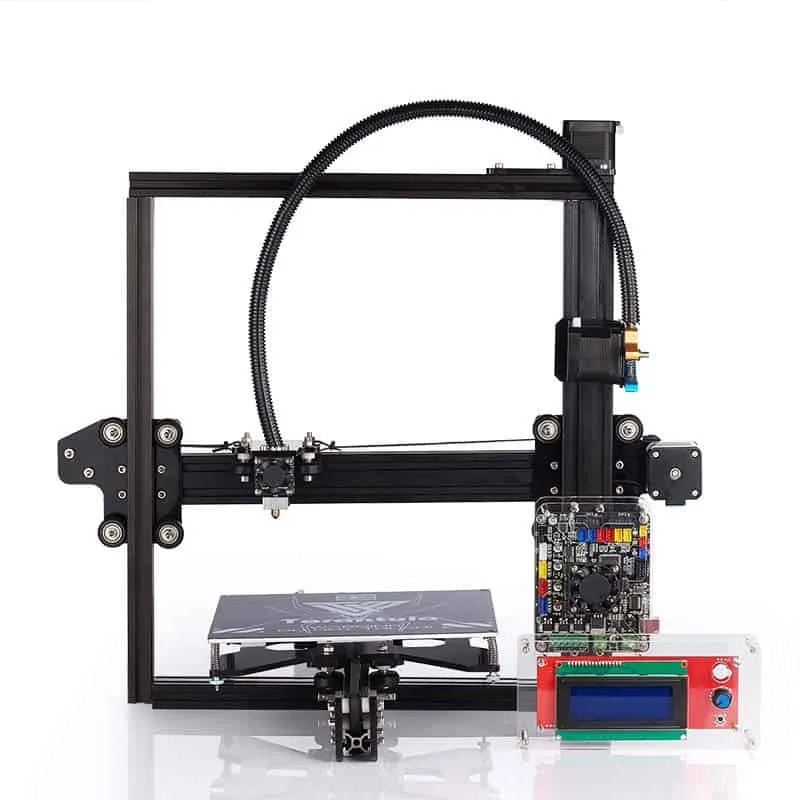

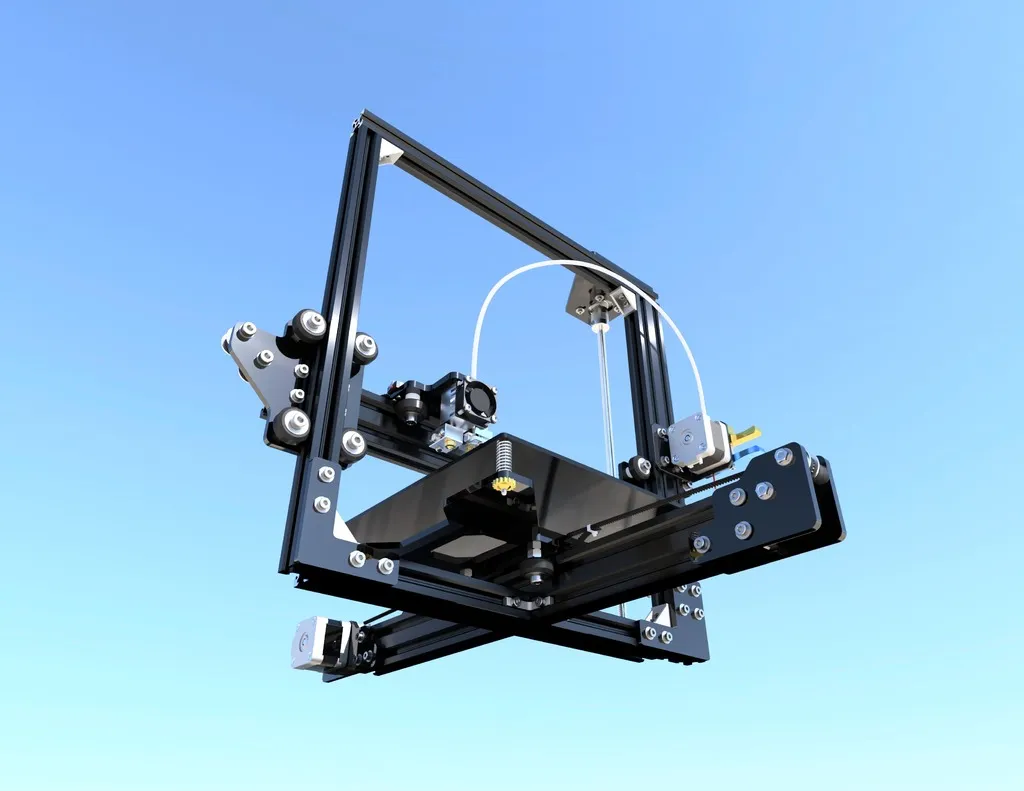

Tevo Tarantula Carbon Fiber Upgrades

The Tevo Tarantula is a popular and affordable 3D printer, known for its ease of use and modifiability. While it can print a wide variety of materials, carbon fiber filament presents a unique challenge and opportunity. Carbon fiber filaments, reinforced with carbon fibers, offer exceptional strength-to-weight ratios, making them ideal for functional parts. However, printing with carbon fiber requires specific upgrades to ensure print quality and printer longevity. This guide will detail the top 5 upgrades that can transform your Tevo Tarantula into a carbon fiber printing powerhouse, allowing you to create strong, durable, and high-performance parts. Each upgrade plays a crucial role in successfully printing with carbon fiber, from nozzle selection to enclosure considerations.

Upgrading Your Tevo Tarantula for Carbon Fiber

Before diving into specific upgrades, it is important to understand why the standard Tevo Tarantula setup is often inadequate for carbon fiber. Carbon fiber filaments are abrasive. The carbon fibers themselves can wear down standard brass nozzles quickly, leading to inconsistent extrusion and print failures. Furthermore, the high printing temperatures and potential for warping necessitate careful consideration of bed adhesion and environmental control. Implementing the right upgrades will protect your printer and enhance your printing experience with this challenging material. These upgrades will not only make it possible to print carbon fiber but will also improve the overall quality and reliability of your prints, extending the lifespan of your printer.

Nozzle Selection for Carbon Fiber

The first and arguably most crucial upgrade is the nozzle. The abrasive nature of carbon fiber filaments means that a standard brass nozzle will quickly wear down, leading to inconsistent extrusion and print failures. Choosing the right nozzle is critical for achieving clean prints and preventing nozzle blockage. Several types of nozzles are suitable for carbon fiber printing, but they must all be abrasion-resistant.

Importance of a Hardened Steel Nozzle

Hardened steel nozzles are a popular and cost-effective choice for carbon fiber. They are significantly more resistant to abrasion than brass, ensuring a longer lifespan and more consistent extrusion. These nozzles are specifically designed to withstand the wear and tear caused by abrasive filaments, making them ideal for carbon fiber. Their durability translates into more accurate prints and less frequent nozzle changes, which can save time and money in the long run. The hardened steel is also good at maintaining a consistent temperature, crucial for carbon fiber printing.

Nozzle Temperature and Settings

When using carbon fiber filament, it’s important to calibrate the nozzle temperature to achieve the best possible print results. Carbon fiber filaments typically require higher printing temperatures than PLA or ABS. Consult the filament manufacturer’s recommended temperature range. Additionally, ensure your printer’s firmware and slicer settings are configured correctly for the chosen nozzle type and filament. The correct nozzle temperature is crucial for proper layer adhesion and the overall strength of the printed part. Experiment with different temperatures within the manufacturer’s range, making small adjustments to find the optimal setting for your specific filament and printer setup. Proper nozzle temperature will also help to prevent stringing and improve the dimensional accuracy of the printed parts.

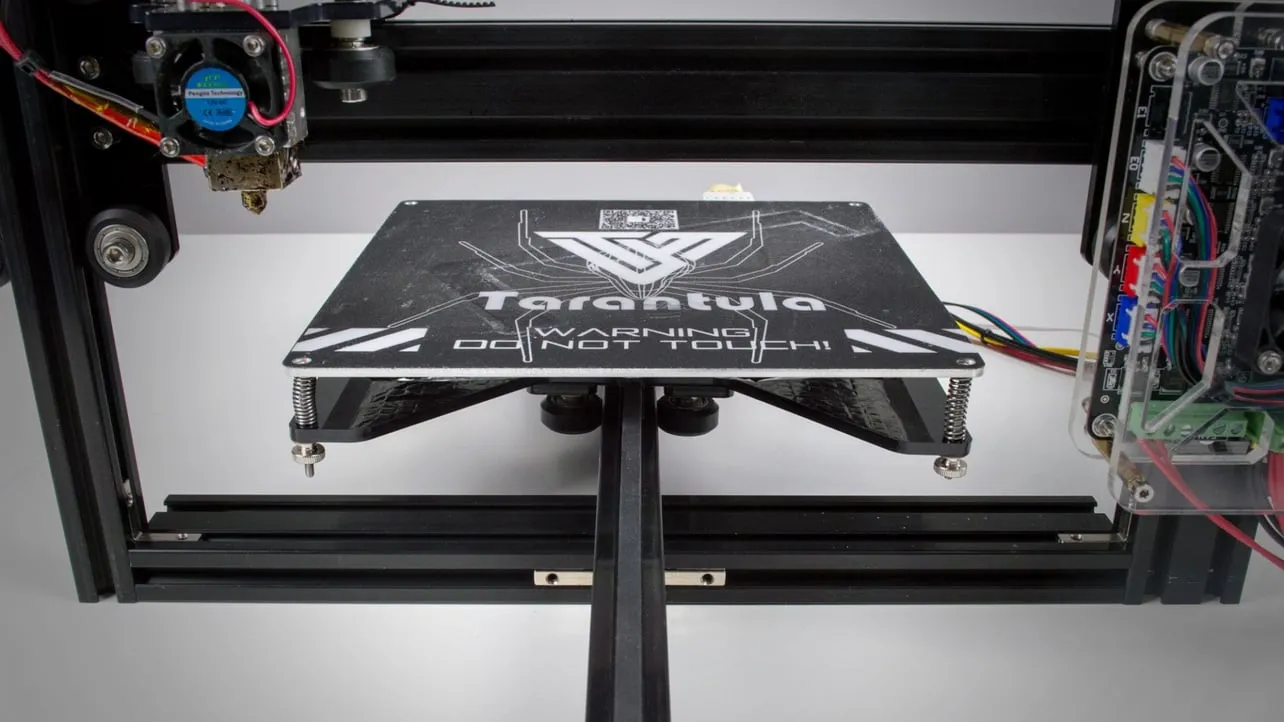

Heated Bed and Bed Adhesion

Carbon fiber filaments often warp during printing, especially on larger parts. A heated bed is essential to mitigate this issue by maintaining a consistent temperature throughout the print and promoting good adhesion to the print surface. Without a heated bed, the cooling process can cause the edges of your prints to lift, resulting in print failures. In addition to a heated bed, using the right bed surface and adhesive will help with adhesion.

The Ideal Bed Temperature for Carbon Fiber

The ideal bed temperature for carbon fiber filaments varies depending on the specific filament and the manufacturer’s recommendations. Generally, carbon fiber filaments require bed temperatures between 60°C and 80°C. This temperature helps to ensure that the first layer adheres well and prevents warping. Always check the filament’s specifications for the recommended bed temperature. A consistent bed temperature across the entire surface is also critical. Make sure your printer’s bed is properly leveled and that the temperature is consistent across the print surface, to avoid inconsistent adhesion.

Adhesion Solutions for Carbon Fiber

Achieving good bed adhesion is essential when printing carbon fiber. Several solutions can improve adhesion and prevent warping. Common options include using a glue stick (like Elmer’s), Kapton tape, or a dedicated 3D printing bed adhesive. These products create a surface that the filament can stick to more readily. Additionally, ensuring your bed is properly leveled and cleaning the bed surface before each print is also important. A clean bed surface allows the filament to adhere more effectively. Using a brim or raft in your slicer settings can also provide extra surface area for the first layer to adhere to the bed, further reducing the risk of warping.

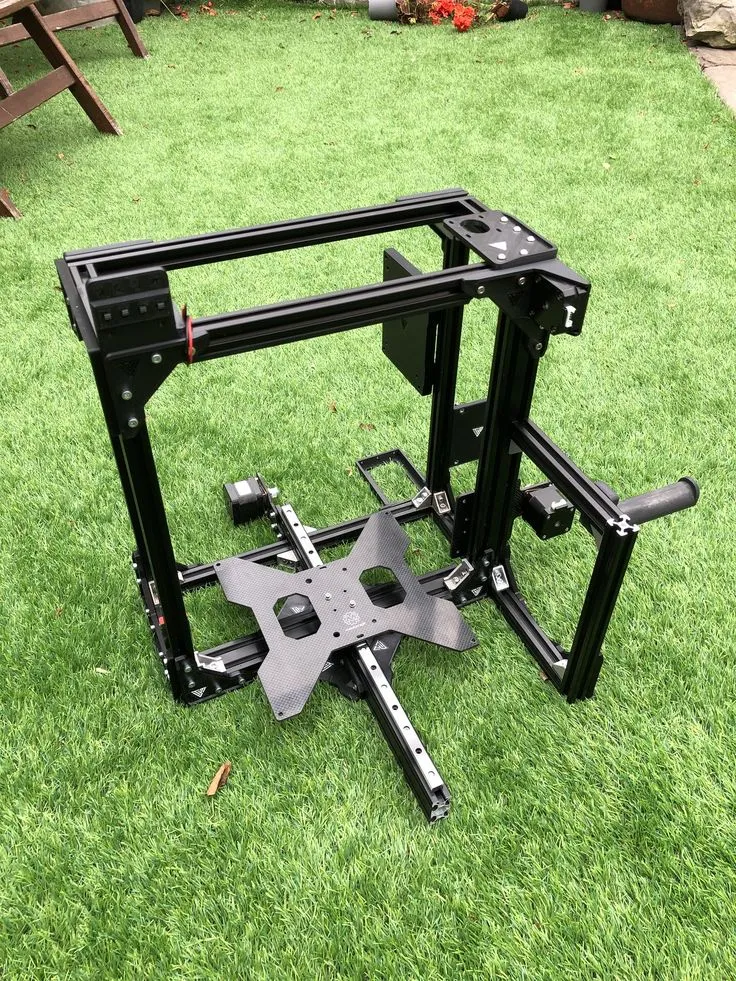

Extruder Upgrades for Carbon Fiber

The stock extruder on the Tevo Tarantula may not be the best choice for carbon fiber. The abrasive nature of the filament can cause wear on the extruder’s components, leading to under-extrusion or inconsistent filament feeding. Upgrading your extruder can improve reliability and print quality. There are various types of extruders available, and selecting one designed for abrasive filaments is a critical upgrade. This ensures that the filament is fed smoothly and consistently to the nozzle. There are two main types of extruders that will help.

Direct Drive Extruder Benefits

Direct drive extruders place the extruder motor directly above the hot end. This setup offers several advantages for carbon fiber printing, including better filament control and reduced stringing. With a direct drive, the filament path is shorter and more direct, leading to more precise extrusion and reduced flex. The direct drive configuration helps to minimize the distance the filament travels from the extruder to the nozzle. The increased control offered by a direct drive extruder is particularly beneficial when printing intricate designs or parts with fine details using carbon fiber.

The Importance of a Reliable Extruder

Regardless of the type, a reliable extruder is essential for carbon fiber printing. Look for extruders made from durable materials, such as aluminum or hardened steel, to withstand the abrasive nature of carbon fiber filaments. The extruder should provide consistent and accurate filament feeding, minimizing the chances of print failures. Ensure that the extruder is properly calibrated and adjusted to match the specific filament you are using. This calibration is crucial to eliminate issues like under-extrusion or over-extrusion. Regularly inspect and maintain your extruder to ensure it continues to perform reliably.

Enclosure for Carbon Fiber Printing

An enclosure can significantly improve the print quality and reliability when using carbon fiber filaments. Carbon fiber filaments are sensitive to temperature fluctuations and drafts, which can cause warping and print failures. An enclosure provides a stable printing environment, maintaining a consistent temperature and protecting your prints from external influences. Enclosing your printer also helps to contain fumes and reduce the risk of warping.

Benefits of an Enclosed 3D Printer

An enclosure offers several advantages for carbon fiber printing. First, it maintains a consistent temperature, which prevents warping and improves layer adhesion. Second, it helps to reduce drafts and temperature fluctuations, which can negatively affect print quality. An enclosed environment reduces the impact of external factors on the printing process. Finally, an enclosure can help to contain fumes released during printing, improving air quality in the workspace. Enclosures also enhance safety by preventing accidental contact with moving parts or the heated bed.

Controlling the Printing Environment

Beyond simply enclosing the printer, you can also control the printing environment within the enclosure. Adding a temperature sensor and a small heater can help maintain a consistent temperature during printing, especially in cooler environments. Consider using a HEPA filter to remove any potentially harmful particles from the air. Monitoring the temperature inside the enclosure will help you to ensure that it is ideal for your filament. Furthermore, keeping your printing area clean and free of drafts will further enhance the quality of your prints.

Filament Storage and Handling

Carbon fiber filaments, like many 3D printing materials, are hygroscopic, meaning they absorb moisture from the air. This moisture can lead to print defects such as stringing, poor layer adhesion, and surface imperfections. Proper storage and handling are essential to keeping the filament dry and ensuring the best possible print results. Proper storage helps to prevent these problems and maintain the integrity of the filament. In order to ensure a quality product, follow some simple steps.

Protecting Carbon Fiber Filament from Moisture

The primary goal of filament storage is to protect it from moisture. Store your carbon fiber filament in an airtight container with desiccant packs. Desiccant packs absorb moisture from the air, keeping the filament dry. You can also use a dedicated filament dryer, which actively removes moisture from the filament before printing. Avoid storing the filament in humid environments, such as basements or garages. Inspect your filament regularly for signs of moisture absorption, such as hissing sounds or brittle filament.

Best Practices for Filament Storage

Beyond airtight containers, a few best practices can further protect your filament. Always reseal the filament spool’s original bag after use. Store the filament in a cool, dry place, away from direct sunlight. Consider using a filament dry box while printing, especially in humid environments. By following these storage tips, you will extend the life of your filament and improve the quality of your prints. Proper storage is just as important as the printer upgrades themselves.

In conclusion, upgrading your Tevo Tarantula with the right components is crucial for successful carbon fiber printing. From the nozzle to the extruder to the enclosure, each of these upgrades plays a crucial role in ensuring print quality, reliability, and the longevity of your printer. By implementing these 5 key upgrades, you’ll be well on your way to producing strong, durable, and high-performance parts with your Tevo Tarantula. Remember to carefully consider each upgrade and the specific requirements of your carbon fiber filament to optimize your 3D printing experience.